Injectable Drug Development

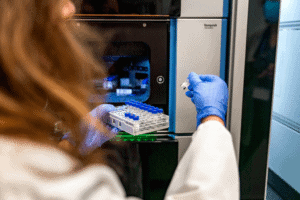

Pre-Formulation and Formulation Development

Pre-Formulation and formulation development clients come to us with a wide range of molecule including small molecules, oligonucleotides, vaccines, peptides, biosimilars, mAbs, and large protiens. We work with our clients to create a new formulation (or optimize an existing formulation) that is suitable for pre-clinical and clinical use. We deliver pre-formulation, excipient and formulation studies of parenteral, oral, and lyophilized formulations. Our goal for injectable formulation development is to obtain a safe, effective product that is stable for years after manufacturing.

- Solubility, pH, Forced Degradation with Heat, pH Adjustments, Peroxide, and Light

- Excipient Studies, Co-Solvent Investigations, Short Term Stability

- Dose and Route of Administration Analysis, Bulk Preparation, pKa and pI Studies

Our knowledgeable and experienced group of scientists can provide injectable drug formulation process development solutions during your product development. As your product moves through the clinical trial process into commercial manufacturing environments, manufacturing scale and processes can change. Our process development team can ensure that you are prepared for the possibilities, and able to produce a reliable product utilizing a robust manufacturing process.

- Lyophilizer – LyoStar II Freeze-Dryer

- Development/Optimization of Lyophilization Cycle

- Crystalline/Amorphous Characterization, Thermal Stability

- Differential Scanning Calorimetry (DSC), Dielectric Analysis (DEA)

- Differential Thermal Analysis (DTA), Thermoelectric Analysis (TEA)

- Freeze-Dry Microscopy, Technology Transfer for Manufacturing

We have extensive experience in analytical development to create a robust method for analysis of your product. Whether starting from scratch or optimizing a method provided by our clients, we offer analytical development services that are customized to your product. We specialize in executing phase appropriate method validations which will support that method during each step in the drug approval process. Read more about our injectable formulation development with complex injectables.

- Method Transfer: Verification, Qualification, Validation

- Method Development/Optimization

- Liquid Chromatography, Gas Chromatography

- Ion Chromatography, Capillary Electrophoresis

- BioAssays, UV-Vis, Particle Analysis